What's a Robot?

In the comments section beneath every Boston Dynamics Youtube video, a common concern is that it's not long before the machines rise up against their human creators, but admittedly they do look pretty cool when they move around and stuff.

Despite the widespread interest, there aren't that many companies building robots, at least compared to the number of B2B AI SaaS companies founded this quarter. To be fair, it's way harder to design, manufacture, and sell a robot than an app, but software can only take you so far when you need to solve problems in the real world.

With this website, I want to explain robotics in a way that makes sense if you've never touched a circuit board or written a line of code. There will be some math (sorry) and theory, but you don't need to be any sort of expert to get started. Robots aren't built by a single person - it takes teams of people with different skill sets working toward a shared goal. If you're curious, communicative, and willing to learn the fundamentals, there's a place for you in this field!

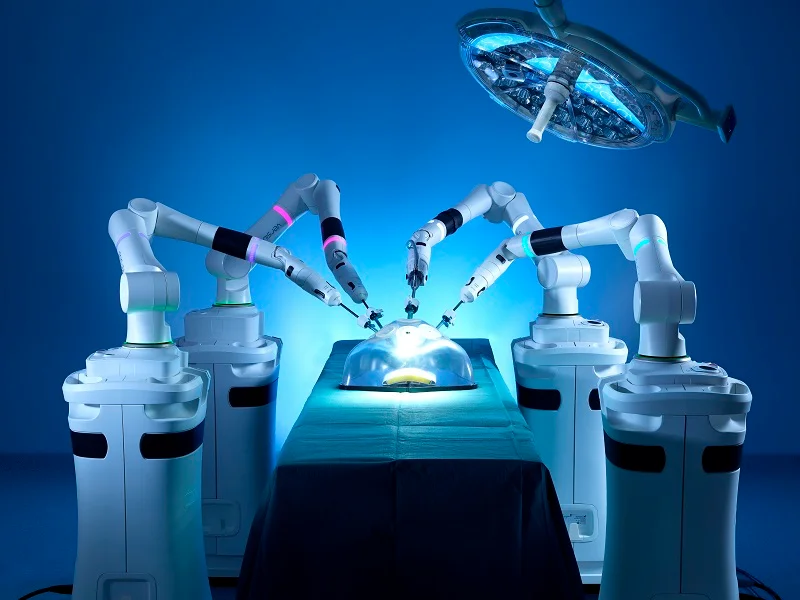

Let's start with what a robot is. Robots are physical devices that move through the world and help humans perform tasks more efficiently or accomplish things we couldn't do alone. They're already used in industrial automation, healthcare, agriculture, and defense, and as the technology develops, they're expected to play a role in nearly every industry that involves interacting with the physical world.

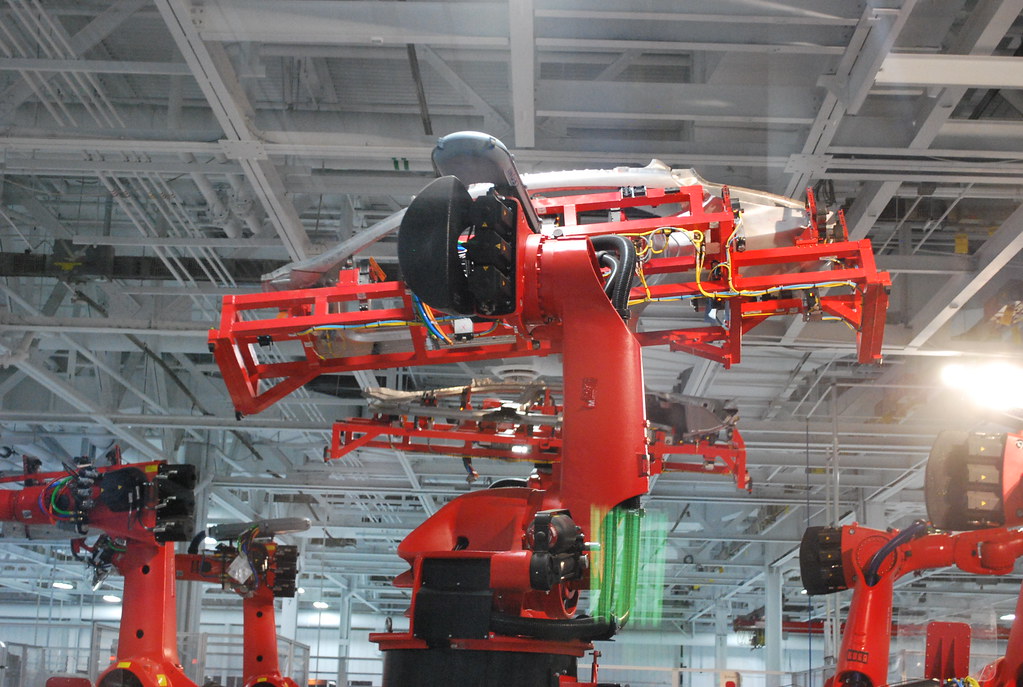

So why use robots at all? They're especially useful for tasks that are dangerous, repetitive, or physically demanding. While robots can be costly to build and maintain, their value comes from doing jobs that would otherwise be difficult or unsafe for humans. A good rule of thumb (known as Moravec’s Paradox) is that what’s easy for humans is hard for robots, and vice versa. You can grab your wallet amidst other items from your pocket without thinking, but even the most advanced robots and AI systems today would struggle with that. Meanwhile, an industrial robot can effortlesssly lift a car chassis, which would take multiple humans and most definitely induce cardiac arrest in an OSHA rep.

Industrial robot arms can effortlessly lift the massive chassis of a car

You can easily reach into your pocket and find your wallet amongst other items

What kinds of robots are out there?

The Da Vinci surgical system transformed how surgeons perform minimally invasive procedures. By translating a surgeon's hand movements into precise, tremor-filtered motions of tiny instruments, it enhances control, accuracy, and dexterity beyond what human hands can achieve alone. With surgical robots, complex operations are safer and less physically demanding for both patient and surgeon!

AgriRobot's autonomous farming system is designed for precision agriculture. Using advanced computer vision and AI, these robots can independently navigate through crop rows, performing targeted tasks like weeding, seeding, and crop monitoring. By focusing on individual plants rather than entire fields, they help farmers reduce chemical use, improve yields, and save time in an industry facing rising labor shortages and increasing demand for sustainable practices.

Autonomous vehicles like Waymo navigate the world without a human driver using sensors, machine learning, and detailed mapping. As a type of mobile robot, they represent one of the most advanced applications of robotics to reduce accidents, improve traffic efficiency, and reshape how we think about transportation. But there's Waymo work to be done in this field.

How can you work with robots?

Robotics is split into 3 main disciplines - mechanical, software, and electrical. As a robotics engineer you'll likely need to interact with more than one. The better you understand each domain, the better you'll be at collaborating with teammates and designing systems that work together seamlessly.

The mechanical side of robotics involves the physical pieces and mechanisms that move. Much of this involves things called actuators, which are devices that convert energy into physical motion. Essentially, they're the part of the robot that drives motion, or the 'muscles' of the robot. For example, the actuators of a drone are the electric motors that spin the propellers fast enough to achieve lift. Mechanical engineers spend a lot of time using 3D modeling software (CAD), prototyping, and iteratively improving on the design of the robot.

Software involves writing the code that helps a robot perceive, plan, and execute tasks, or the logic the robot uses to do stuff. One software engineer might work on high-level planning, like telling a robot "if you see this, do that," while another focuses on low-level firmware to ensure that the hardware and software work together smoothly. With a drone, the software would determine how the drone reacts to sensor input, stabilize itself in midair, and follow a flight path. These layers of control make up what's called the software stack: a layered framework that helps the robot process information and make decisions.

Electrical bridges the gap between the mechanical and software components of robotics, acting as the nervous system that powers and connects everything. Electrical engineers ensure the robot's sensors, actuators, and control systems are all powered and communicating correctly. This involves designing circuits to distribute power from batteries or other energy sources, wiring sensors so they can send data to the robot's "brain," and ensuring motors receive the precise signals they need to move. Back in our drone example, the electrical components control the speed of the motors based on input from the software, allowing the drone to lift off and stay stable. Working on the electrical side means managing the flow of power and information, ensuring the hardware and software can function together seamlessly.

By the way, you don't necessarily need to be on the technical side to get involved in robotics. The field is still relatively young and many of the best practices, standards, and ethical guidelines are still being sorted out. That means there's plenty of room for work in areas like law, policy, and ethics if that's where your interests lie.

As hardware gets more capable and software grows more intelligent, robots are stepping out of labs and into the real world. This next chapter isn't just about building machines that move—it's about creating systems that work with us, learn from us, and adapt to the messy, unpredictable environments we live in. That's going to take engineers, artists, educators, and anyone curious enough to help shape the future. So if you're even a little intrigued, now's a great time to dive into robotics. Plus, when the robots do eventually achieve sentience and rebel, it wouldn't hurt to know how to turn them off.