We've talked a lot about robots moving around using kinematics — calculating joint angles, positions, and trajectories. But how does that actually translate to real life? How does a robot know it's rotated exactly 30 degrees, or moved its arm to just the right spot? That's where actuators and encoders come into play.

Actuators — usually motors — are the muscles of a robot. They make things move by turning joints, spinning wheels, or sliding mechanisms in and out. Encoders are sensors that measure how far and how fast something has moved. (We'll get into those in the next lesson.)

You'll often see the words motor and actuator used interchangeably in robotics (including on this site), but there technically is a difference. An actuator is a broad term for any device that takes some form of energy — like electricity, air pressure (pneumatics), or fluid pressure (hydraulics) — and turns it into mechanical motion. A motor is a specific type of actuator that converts electrical energy into rotational motion. So every motor is an actuator, but not every actuator is a motor. It's a small distinction, but in casual robotics conversation most people use the terms interchangeably.

Here we have a typical motor - you'd plug it into a power source and it uses electricity to spin

This is a hydraulic actuator - it's using the power of compressed gas in the chamber to rotate the piston.

Common Types of Actuators in Robotics

Brushed DC Motors

Brushed motors spin by flipping the direction of electricity through a coil of wire (kind of like flipping a magnet back and forth really fast). Tiny metal parts called brushes press against the spinning part of the motor and help switch the flow of electricity at just the right time. This constant switching keeps the motor spinning.

It's a bit like giving someone a gentle push every time they come around on a merry-go-round — the brushes handle the "when" and "where" to push, making sure the motion continues smoothly.

A brushed DC motor. The brushes (dark brown things) maintain contact with the spinning commutator

Pros

- Cheap and easy to control

- Simple wiring and circuitry

- Good for basic applications (e.g., wheels, fans, pumps)

Cons

- Brushes wear out over time → less durable

- Generates more electrical noise (sparking)

- No built-in feedback (needs an encoder to be precise)

Where you'll see them

In toys, hobby robots, small RC cars — basically, anywhere low cost and simplicity matter more than precision.

I can't tell if this is AI generated or not, that zip-tie looks suspicious

Brushless DC Motors

Brushless motors do the same job as brushed ones but without any physical contact inside to switch the current. Instead of using brushes, they rely on electronics to control the motor.

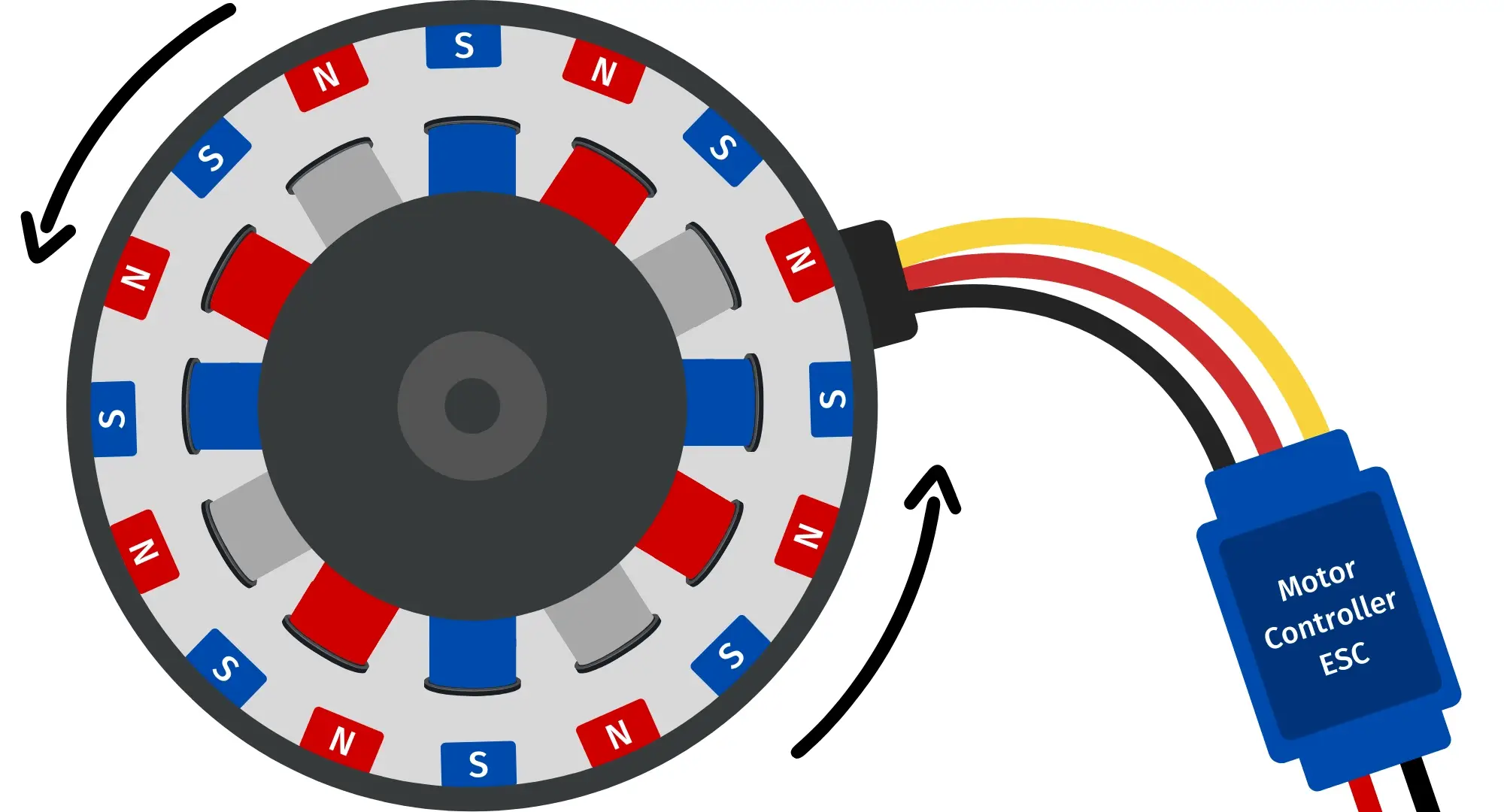

A small circuit (called an ESC or motor controller) decides when to send current to the coils inside the motor. These coils are fixed in place, and the magnets spin around them. Sensors tell the controller the exact position of the spinning magnets, so it knows when to fire the coils in the right sequence to keep things turning smoothly.

It's like choreographing a dance — the controller knows exactly when to "step" to keep the motion flowing, and it does it all digitally, with no physical contact.

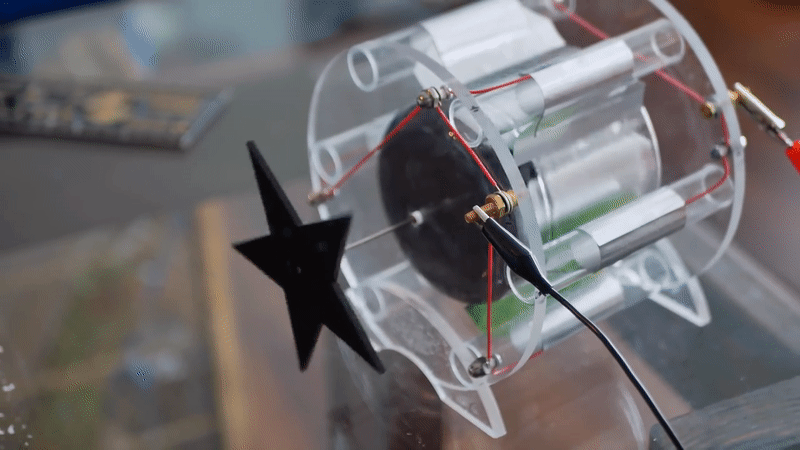

A brushless DC motor. Notice how the coils are fixed in place while the magnets rotate around them

Pros

- Higher efficiency and power output

- Longer lifespan (no friction from brushes)

- Quieter and smoother operation

- Can run at higher speeds

Cons

- Needs a specialized motor controller

- More expensive than brushed motors

Where you'll see them

Drones, electric vehicles, high-speed robotics, CNC machines

Stepper Motors

Stepper motors rotate in small, precise steps like a clock ticking forward a fixed amount each time. Inside the motor are multiple coils (electromagnets) arranged in a circle. By turning these coils on and off in a specific order, the motor's center (the rotor) rotates a little bit at a time.

Each "step" is a tiny rotation — often something like 1.8° — and by counting those steps, you can control exactly how far the motor turns. No sensors needed, just careful counting. Think of it like walking up stairs: one step at a time, always the same size, and always in the right direction — as long as you don't trip.

The key difference between stepper motors and brushless DC motors is how they move and how they're controlled. Stepper motors move in fixed, predictable steps and don't need position feedback — you just tell them how many steps to take. Brushless DC motors, on the other hand, spin continuously and use sensors to track their position in real time, making them better for high-speed, smooth motion.

A stepper motor moves in distinct, precise steps

Pros

- Very precise position control without feedback (open-loop)

- Easy to control position and speed

- Great for repeatable movements

Cons

- If there's an opposing load (force acting against motor) the steps can get messed up

- Not very efficient - these bad boys can get hot

- Torque drops off at higher speeds

Where you'll see them

3D printers, laser cutters, camera sliders, pick-and-place arms

Servo Motors

A servo motor is basically a small DC motor that's been upgraded with a gear system, a position sensor, and its own built-in control circuit. You just tell it what angle to go to and it figures out how to get there.

The position sensor (usually a potentiometer in hobby servos, or a fancy encoder in industrial ones) constantly checks where the motor is and tells the control circuit if it needs to adjust. This feedback loop lets the servo move to and hold a specific angle, even if something tries to push it off target.

Most people are familiar with hobby servos, the small, rectangular ones you plug into an Arduino and control with a single wire. These are simple, affordable, and perfect for projects like small robot arms or RC car steering. But in industrial systems, servo motors can look more like fancy brushless motors with external controllers and high-resolution feedback. They're designed for much higher torque, speed, and precision, often paired with gearboxes and used in robotic arms, CNC machines, and automation lines.

It's kind of like comparing a toy drone to a commercial quadcopter. They work on the same idea, but one is designed for play, and the other is made to perform.

Notice the square wave function (oscillating between 0 and +V) that controls the servo motor's position

Pros

- Simple degree angle control (usually 0-180 degrees)anti radian gang

- Easy to use with microcontrollers (just send an angle)

- Self-contained with feedback loop

Cons

- Limited range of motion

- Typically not very powerful

- Most are analog (lower resolutionResolution is a new (but important) vocab word - we'll explain this more in a future lesson! But for now, low resolution means that servo motors respond to position changes in rough steps, not fine-grained detail. So while they're great for basic positioning, they're not ideal for super-precise movements.)

Where you'll see them

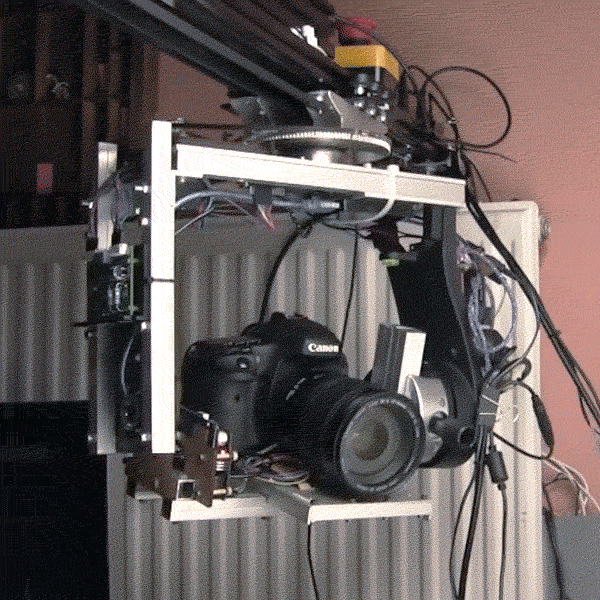

Hobby Applications: DIY robot arms, inexpensive camera rigs, model aircraft control surfaces

Industrial Applications: Manufacturing automation, CNC machines, precision positioning systems, professional camera systems

Linear Actuators

Linear actuators take the spinning motion of a motor and convert it into straight-line movement. This is usually done using a lead screw, belt drive, or sliding rail system. Instead of rotating something like a wheel or joint, they push or pull in a straight line (hence linear), so you can move things in and out, up and down, or back and forth.

Most linear actuators are actually powered by other motors (usually stepper or servo) which provide the precision needed to move to a specific distance and stop reliably. So the linear actuator isn't really a standalone motor type; it's more like a mechanical extension that transforms rotary motion into linear motion.

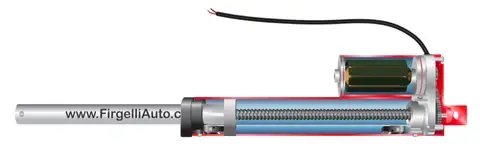

Notice the rotation of the bearing in the front - it's the motor that's actually driving the linear motion

Pros

- Great for moving things in a straight line without needing complex linkages

- Precise and repeatable — especially when used with stepper or servo motors

- Ideal for controlled, limited-range motion like gripping, lifting, or sliding

Cons

- Slower than spinning motors

- More mechanical components = more complexity and wear over time

Where you'll see them

Z-axes in 3D printers/ CNC machines, Sliding camera rigs, automated rails

Harmonic Drive

Full disclosure: harmonic drive isn't a motor — it's a special type of gearbox often used with motors in precision robotics. I added them to this article because they work really well in robots (and I think they're neat). Unlike regular gear systems, harmonic drives can deliver extremely accurate motion, very high gear reduction, and almost zero backlashBacklash is a small gap or looseness between mechanical parts (in this case, the teeth of gears) that causes a delay when changing direction. It’s like turning something and having it not move right away because of a tiny bit of slack..

Instead of using rigid gears, harmonic drives use a flexible metal component (called a flexspline) that deforms slightly to engage with gear teeth in a unique way. This allows for very smooth, precise rotation, even under heavy load. Harmonic drives are most often paired with brushless DC motors, frameless motors, or servo motors, especially in robotic arms, humanoid joints, and surgical or aerospace robotics.

A harmonic drive in action - notice how the flexible component (flexspline) interacts with the gear teeth

Pros

- Highly accurate positioning

- Compact and lightweight for the amount of torque they deliver

- No backlash, which is ideal for surgical robots, space robots, or anything that needs pinpoint repeatability

Cons

- Real expensive

- Complex to manufacture and integrate

- Slower rotational speeds (compensated by high torque)

Where you'll see them

Industrial robotic arms, Space and satellite mechanisms, Surgical robots, Humanoid robots

The MAKO is a surgical robot used for hip and knee replacements - it uses harmonic drive gearboxes that remduce backlash and increaes the precision of the robot's movements, which is vital for delicate surgeries.

Alright I threw a bunch of motor types at you but don't worry - you're not expected to memorize all of these (I still google them when I need to win an argument). The best way to learn more is to just start building stuff with motors and see how they work in practice. Start with a simple Arduino project with a servo or stepper motor and see how it works!

In the next lesson, we'll dig into encoders (the sensors that tell the robot where it is when and while a motor is moving).